|

PISTONS &

RINGS

TECH TIPS |

Ring seal is one of most important things people should

pay attention to.

So important, that NASCAR engine builders will actually bore and hone

their cylinder blocks to a preheated full temperature to insure things

are consistent when racing. What happens during cold start-ups?

They don't, the motors are pre-heated before start-up.

So important, most performance engine builders will use vertical gas

ports to expand and push the rings against the cylinder walls. With

introduction of modern oils, the gas ports will not clog up like the

olden days.

So important, vacuum pumps were mainly introduced to keep the ring seal

connected at higher RPM.

So important, due to the fact that rings are main contributor to disperse

piston heat. (Aside from under the piston oil sprayers) Ring

thickness has been reduced from the olden days to a happy medium for

specific applications.

Thick rings cool better and thin rings have many advantages until cooling is

a problem.

So important, ring tension against the cylinder wall for the compression

and oil rings is measured when installing or building performance motors and

is something that only high-level builders have access to. (Meaning a verity

of rings to choose from)

Anyway...

Let's stay to perimeters Honda has

given us and the parts available to us, to keep it simple.

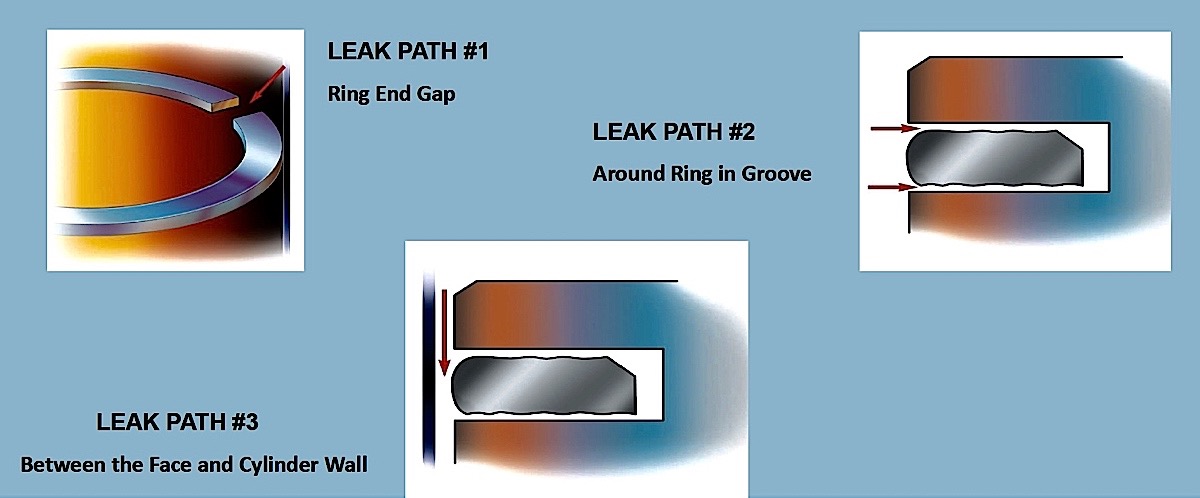

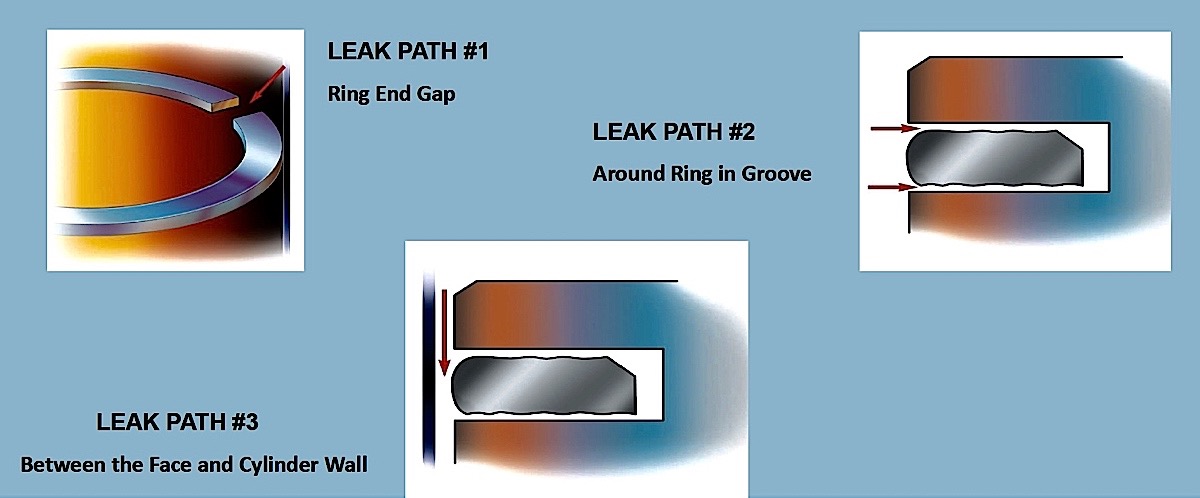

Leak path #3 will be talked about below and is critical to

get ring seal as good as possible.

Leak path #2 is what many people experience when using old technology

pistons or used pistons.

New rings will never help if the ring grooves are worn, distorted or not

perfect. Worn ring grooves can only be measured with the best and most

accurate measuring equipment.

Using new rings with bad rings grooves will have you leave plenty of

horsepower on the table.

Too vertical or steep of a angle can

create excessive blow-by. Also, there could be high ring rotation speeds

that could lead to ring end gaps to align on the piston.

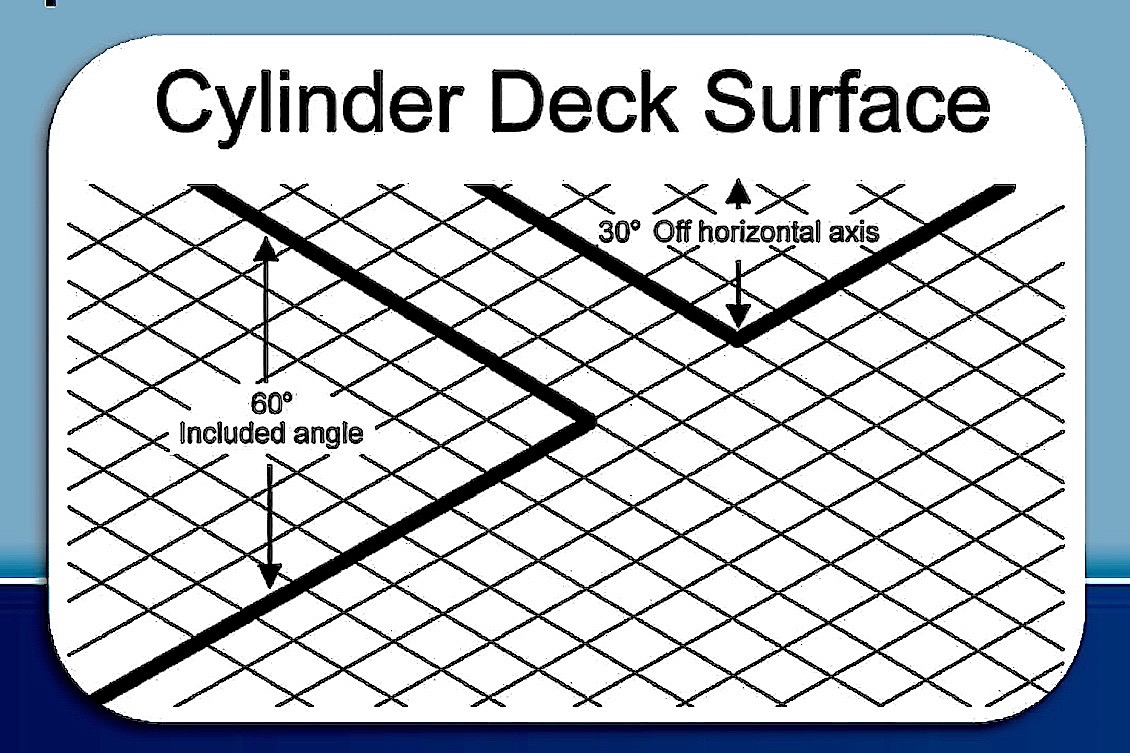

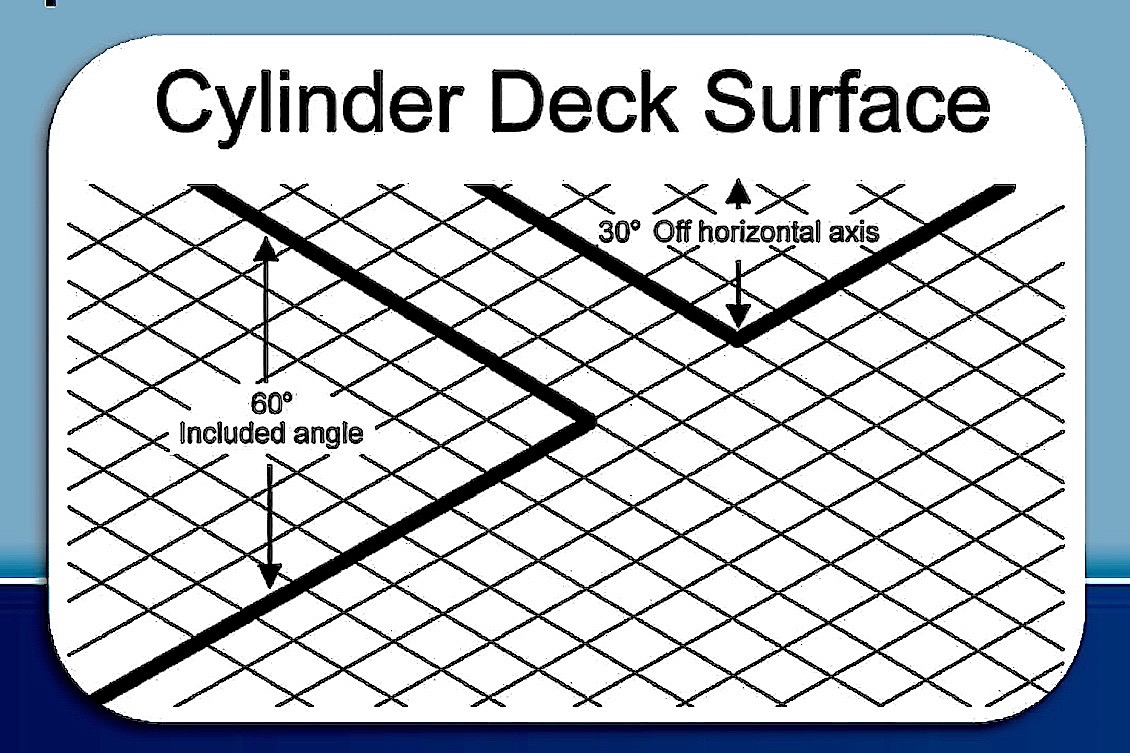

In the Honda world with cast iron cylinder liners, here's

what we do!

After boring the cylinder.

We use 220 grit stones to create valleys for oil. Generally about .002 from

final size.

We use 280 grit stones to eliminate peaks and maintain valleys.

Then we follow up with a cylinder finisher, heavily oiled and about 18

strokes per cylinder.

The cylinder finisher kinda looks like a chimney sweeper. (We will get you

a photo soon)

When assembling it would be advised to oil the inside of the piston ring

grooves.

In the break-in period the rings can get too hot and cause a bit of

micro-welding. Generally seen as light speckling on the sides of the rings. (Aluminum)

The pistons are now shot.

Here's what we do...

When first starting the motor, we will cover start-up in greater detail

later. But, this is ring talk right now.

Start the motor and run for 15 seconds and let it cool.

Start the motor for 15 seconds and let it cool.

Start the motor for about 60 seconds and let it cool.

Start the motor and run for a few almost full temperature several times. (Until you feel heat in the lower cases)

This is ring thing, our break-in and running procedures will come later.

Some

basic static ratio guidelines:

|

7-8 to 1 :

This range works for blown or turbo-charged engines. These engines

typically use later closing inlets to over fill the cylinders.

9-10 to 1:

This range is very easy to work in and gives good results in power

output and general manners.

10-11.5

to 1:

This is a range we use in our high output street engines when

we can control all components as a total package. By using piston

squish and quench to our advantage, exceptional power can be

obtained on a street driven motorcycle.

11.5 +:

These high compressions are used in racing applications and the

overall performance. |

To be continued (Break-in and piston

configurations)

A 3.99% customer service

charge is applied to all phone orders.

If ordering via phone,

please also provide the part # of any products you are interested in for faster

and more accurate service.

If you encounter a (rare)

broken button as you're trying to add parts to your cart (going to PayPal

summary instead of your cart or not opening PayPal at all) or anything else of

concern, please call us to report it. We'll try to have it fixed for your

convenience within the next 5-10 minutes. Afterwards, refresh the page and try

again.

NOTE: As of July 1st,

2018, an extended goods and services tax (GST) has been applied to all

Australian consumers buying overseas, charging an extra 10% in taxes to us with

each purchase. To ensure that you can continue to purchase from us in Australia

and we can provide our parts at our usual lower cost, please

contact us at the email below if interested in any particular

parts so that we can make a special shipping arrangement for you.

It is the sole and

exclusive responsibility of the purchaser to determine the suitability of any

part, product or work for his or her use.

The purchaser shall assume all legal, personal injury risk and liability and all

other obligations, duties and risks therewith.

There is no warranty on High Performance products.

Click

to go back to our home page

Cycle

X Global Headquarters

6246 US

Hwy 51 South

Hazelhurst,

WI 54531

Phone:

715-356-7346

Email:

hotrodcyclex@gmail.com