|

"I just want to thank Ken at Cycle X for all his assistance with my clutch problems. I had a Barnett extra plate clutch, and although it didn't slip, it had jerky and noisy engagement. I tried a different clutch and that engaged smoothly and quietly but slipped in the upper gears. Cycle X 6 spring conversion cured all these problems. I've attached some pictures of my bike. Thank you." - Turbo Gregg |

|

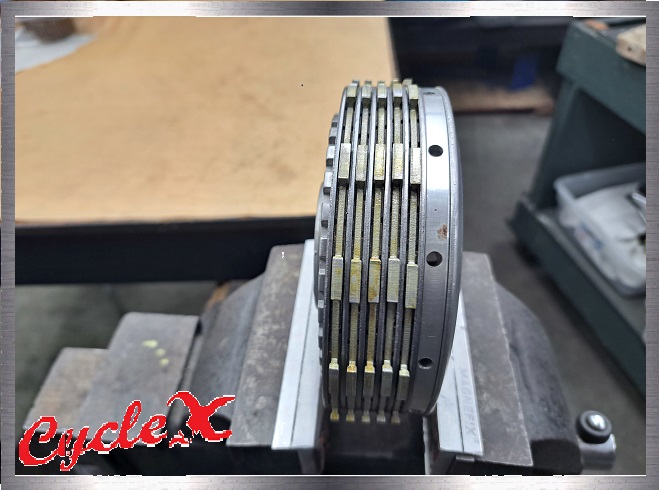

The Ultimate Clutch Kit! Why is this the "ultimate" system? We've corrected some of the problems with the Honda CB750's and included high-end products to complete the kit. We have continued developing the Cycle X system and people are raving about the 5 plate system. Above picture show how it is to be installed.

Can't tell if you have an

early or late model? These instructions should help you identify. |

|

New Six Spring

Honda CB750 SOHC Clutch System for High Horsepower

Applications. The six spring, seven friction and steel clutch system is a bolt-in upgrade for your Honda CB750 SOHC hot rod. These systems have been around for years and are generally used on 90+ horsepower Hondas or synthetic oiled race bikes. The frictions, steels, and springs are interchangeable with all CB750 SOHC models up to 1978.

Cycle X 6 spring clutch system

benefits:

Kit includes:

Note:

This kit consists of new, modified and refurbished Honda

parts. BACK IN STOCK! ENL-030 $799.00 |

|

New! Lock

Up Clutch

(33% Lighter) $ 499.00 -

CALL OR E-MAIL TO ORDER |

|

|

|

|

Heavy Duty Billet Lifter Plate

Have you ever broke an OEM lifter plate when

tightening the clutch springs?

Anyway, here are some heavy-duty billet

lifter plates with new bearings installed.

ENL-036

$63.95 |

|

|

GOLDWING

DOHC

|

|

Best Honda CB750 cable in the world!

These clutch cables were

made for us and feature heavy duty outer sheath and

nylon lined inner tube. Even the internal wire has a bit

of nylon incorporated into it. You will never have a

smoother clutch cable feel and smoother operating

clutch. The cables will be available in standard and

minus 3 inch lengths and minus 5 for you clip-on handle bar folks.

|

|

|

Barnett Clutch Plates (69-78) Honda CB750 SOHC

These Barnett clutch plates

have been added to our large line-up of clutching options for Honda

CB750s from mild to big horsepower applications.

ENL-034 $88.95 |

|

|

New Steels (Tumbled)

These

steels are world class quality and tumbled to remove possible sharp

edges.

ENL-032

$9.49 each steel |

|

|

Drilled Outer Clutch Hubs These hubs are accurately

drilled to reduce weight and help with additional oiling.

Can't tell if you have an

early or late model? These instructions should help you identify.

Call to order.

Exchange basis only.

|

|

STANDARD BARNETT GOLD CLUTCH SPRING SET

|

|

Clutch Spring Shims Comes in sets of

eight. (8) Great for adjusting pressure to springs.

$12.95 ENL-024

|

|

Honda CB750 Clutch Nut Socket

|

A 3.99% customer service charge is applied to all phone orders.

If ordering via phone, please also provide the part # of any products you are interested in for faster and more accurate service.

If you encounter a (rare) broken button as you're trying to add parts to your cart (going to PayPal summary instead of your cart or not opening PayPal at all) or anything else of concern, please call us to report it. We'll try to have it fixed for your convenience within the next 5-10 minutes. Afterwards, refresh the page and try again.

NOTE: As of July 1st, 2018, an extended goods and services tax (GST) has been applied to all Australian consumers buying overseas, charging an extra 10% in taxes to us with each purchase. To ensure that you can continue to purchase from us in Australia and we can provide our parts at our usual lower cost, please contact us at the email below if interested in any particular parts so that we can make a special shipping arrangement for you.

It is the sole and

exclusive responsibility of the purchaser to determine the suitability of any

part, product or work for his or her use.

The purchaser shall assume all legal, personal injury risk and liability and all

other obligations, duties and risks therewith. There is no warranty on High Performance products.

Click to go back to Engine Parts page

Cycle X Global Headquarters

6246 US Hwy 51 South

Hazelhurst, WI 54531

Phone: 715-356-7346

Email: hotrodcyclex@gmail.com

GOLDWING DOHC

( OUT OF STOCK )

GOLDWING DOHC

( OUT OF STOCK )