|

|

|

|

CLUTCH & CHAIN WHEEL TECH TIPS |

Clutch and Chain Wheel

|

|

|

This addition to our refurbished Honda CB750 section is

something that many people are aware of, but sometimes ignore. Meaning, the

cush drive rubbers on the inside of the hub that are disintegrated about 50%

of the time. Call it father time or they just lead a hard life.

So here's what we do...

We disassemble the cush drive and glass bead for inspection. The inner

portion of the hub is drilled and tapped for screws to replace the long

rivets installed by Honda to hold the drive together.

Before installing the new cush drive rubbers, we measure the amount of

deflection or wobble the two sprockets have. Most hubs have different

measurements. But, they generally deflect or wobble over 2mm measured by the

outer tooth area, relying on the cush rubbers to keep things somewhat

stable.

With that said, we surface the outer plates and machine the inner portion to

reduce this deflection and wobble.

Before we install the specific length and material cush drive rubbers, we

remove and install (2) new needle bearings on the inside.

The cush drive is now assembled and ready to go.

By the way...

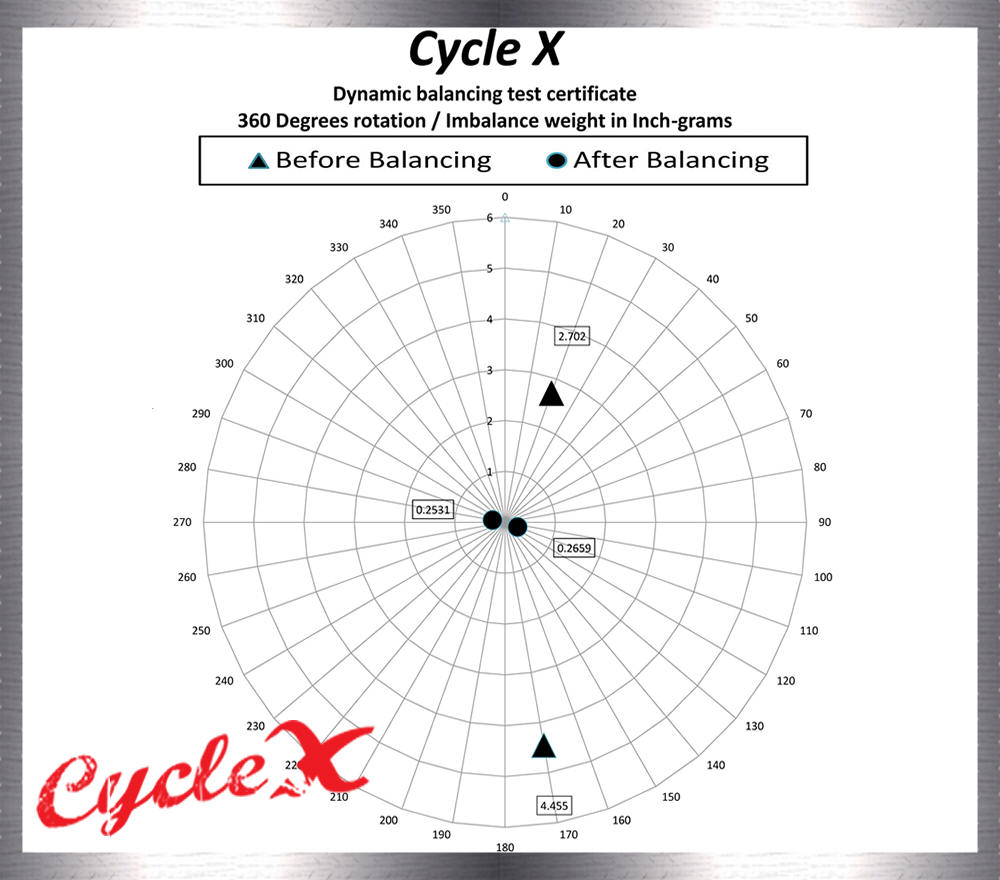

Like crankshafts and alternator rotors, the cush drives and outer steel

clutch hubs are not balanced.

As an option, we are also offering balancing the cush drive and outer steel

clutch hub as a unit.

Because real life stories are sometimes better than written words, our Honda

CB750 vintage heavyweight super-bike road-racer had this same cush drive

process done to it in 2012 and the motor is still together and running

strong after all these years. The bike was sold and is still racing in

Ireland.

Balancing

Barnett clutch info from

years ago...

CB750 SOHC (This set is packaged to cover all years)

All models/years use 7 friction plates, 6 steel plates and 4 springs.

FRICTIONS

Models through 1975 use 7 "A" frictions with 13.3mm wide drive tabs. Models 1976 and later use 6 "A" frictions and 1 "B" friction with 15.9mm wide tabs.

STEELS

Models through 1975 use 6 steels @ 2mm thickness. All K-6 and "F" models, 1976 and later, use 5 steels @ 2mm and 1 comp. steel plate @ 4.8mm.

Note: The use of the comp. steel was a mid-1975 change.

CLUTCH PACK THICKNESS

7 frictions and 6 steels @ 2mm thickness = 37mm (1.460"); 7 frictions, 5 steels @ 2mm thickness, 1 @ 4.8mm comp. steel = 39.7mm (1.560").

CLUTCH SPRINGS

MT-15-4 (56 lb springs)

MT-10-4 (66 lb springs)

When in doubt, check your service/parts manual.

Check it out!

Coated steel clutch plates removed from a drag bike with almost 400 runs.

If there was any question whether our coated steels pass the test of time and

abuse, click on the photo.

To be continued (Crankshaft, alternator rotor and clutch/chain wheel

balancing)

A 3.99% customer service charge is applied to all phone orders.

If ordering via phone, please also provide the part # of any products you are interested in for faster and more accurate service.

If you encounter a (rare) broken button as you're trying to add parts to your cart (going to PayPal summary instead of your cart or not opening PayPal at all) or anything else of concern, please call us to report it. We'll try to have it fixed for your convenience within the next 5-10 minutes. Afterwards, refresh the page and try again.

NOTE: As of July 1st, 2018, an extended goods and services tax (GST) has been applied to all Australian consumers buying overseas, charging an extra 10% in taxes to us with each purchase. To ensure that you can continue to purchase from us in Australia and we can provide our parts at our usual lower cost, please contact us at the email below if interested in any particular parts so that we can make a special shipping arrangement for you.

It is the sole and

exclusive responsibility of the purchaser to determine the suitability of any

part, product or work for his or her use.

The purchaser shall assume all legal, personal injury risk and liability and all

other obligations, duties and risks therewith.

There is no warranty on High Performance products.

Click to go back to our home page

Cycle X Global Headquarters

6246 US Hwy 51 South

Hazelhurst, WI 54531

Phone: 715-356-7346

Email: hotrodcyclex@gmail.com