Camshafts

Advancing and Retarding the

Camshaft

|

Begins Intake

Event Sooner -

Advancing |

Delays Intake

Closing Event -

Retarding |

|

Open Intake

Valve Sooner |

Keeps Intake

Valve Open Later |

|

Builds More

Low-End Torque |

Builds More

High-RPM Power |

|

Decrease

Piston-Intake Valve Clearance |

Increase

Piston-Intake Valve Clearance |

|

Increase

Piston-Exhaust Valve Clearance |

Decrease

Piston-Exhaust Valve Clearance |

Changing the Lobe Center

|

Begins Intake

Event Sooner -

Tightening lobe center |

Delays Intake

Closing Event -

Spreading lobe center |

|

Open Intake

Valve Sooner |

Keeps Intake

Valve Open Later |

|

Builds More

Low-End Torque |

Builds More

High-RPM Power |

|

Decrease

Piston-Intake Valve Clearance |

Increase

Piston-Intake Valve Clearance |

|

Increase

Piston-Exhaust Valve Clearance |

Decrease

Piston-Exhaust Valve Clearance |

A Good Start

At max lift, top retainer to valve guide seal should .030 minimum.

At max lift, minimum of .015 between three coils for a total clearance

of .045 of clearance. (Springs)

With both valves open, minimum of .040 clearance is needed.

Piston to cylinder head clearance (with head gasket) should be .030.

(Steel rods)

Piston to intake and exhaust valve clearance should be .050 intake and .080

exhaust. (Checked at various degrees)

Why do cam manufactures say "must be used with 12.1 or more compression

pistons"?

When looking at the power output of a engine, the mass or volume of the

trapped charge is the important thing.

With a static (not running) look, flow dynamics are not present. But once

the engine starts turning or running, everything changes.

At low RPM or cranking speed with a later closing intake valve with

performance camshafts the cylinder fill is reduced.

When the engine starts its combustion cycle, RPM and exhaust pulses are

introduced to the game, things greatly change.

Closing the intake valve later with performance cam shafts at higher RPM

will allow more flow inertia resulting in more cylinder fill.

Because a later closing intake valve with performance camshafts and the

cylinder fill reduced at lower RPM the term corrected compression ratios is

often mentioned.

Hence: The statement use 12 or more compression

pistons are needed.

We have our favorite ways to increase or correct compression ratios on Honda

CB750 engines. A look at the piston section might be advised.

But, in the mean time, Here is a "quick reference" of

some off-the-shelf piston and recommended camshaft choices.

Stock domed and those inexpensive eBay 836cc similar domed

pistons will be limited to our CX-1 or KHD CX-1 camshaft because of the

valve pockets.

10.25 to 1 compression ratio pistons like Wiseco and others

have the compression ratios and valve pockets to use CX-1, CX-2, KHD CX-1 or

CX-3 camshafts.

12.5 to 1 compression ratio pistons like Wiseco and others

have the compression ratios and valve pockets to use CX-3, CX-4 and CX-7

camshafts.

Camshaft Stuff from the 70's Era

Interesting? Maybe!

Note: You will notice some of the manufactures do not state where these

numbers were measured from.

SIG ERSON

Honda CB750 4 Cylinder SOHC/Proferal Billet 1.1 to 1

Ratio

|

Grind Number |

Cam Part Number |

Timing |

Valve Clearance |

Valve Lift |

Duration |

General

Characteristics |

|

RB282 |

1000 |

I.O. 37 I.C. 65

E.O. 65 E.C. 37 |

.004"

.004" |

.375"

.375" |

282°

282° |

The ultimate street and touring cam

for the 750. Provides increased performance from idle through top

R.P.M. Easy starting and smooth idle. Clears stock pistons, no

machine work required for installation. |

|

*SS288 |

1001 |

I.O. 40 I.C. 68

E.O. 68 E.C. 40 |

.004"

.004" |

.395"

.395" |

288°

288° |

Street, touring, drag strip, cafe

racer. Increased performance from 3500 R.P.M. up. Slightly higher

idle speed, but smooth. Valve to piston clearance must be checked. |

|

*SS298 |

1002 |

I.O. 45 I.C. 73

E.O. 73 E.C. 45 |

.004"

.004" |

.420"

.420" |

298°

298° |

Strong mid range and top end cam

for the hot street and strip machine. Big power increase from 5000

R.P.M. up. Must have added valve to piston clearance. |

|

*SS310 |

1003 |

I.O. 51 I.C. 79

E.O. 79 E.C. 51 |

.004"

.004" |

.400"

.400" |

310°

310° |

Upper mid range and top end cam.

Drag strip, road racing, all out road burner. Needs improved exhaust

and proper gearing for best results. Great in bored and stroked

engines. Runs hard! |

|

*DS324 |

1004 |

I.O. 54 I.C. 90

E.O. 90 E.C. 54 |

.004"

.004" |

.425"

.425" |

324°

324° |

Drag strip, time trails, road

racing, etc. Top end power cam, pulls hard from 7500 R.P.M. up. Well

suited to large displacement engines. Needs good exhaust system. |

H750 valve spring kit is recommended with

all cams for best results.

Titanium retainers are only recommended for

all out racing applications where high R.P.M will be maintained.

*These cams must be carefully checked for

valve to piston clearance. Most high performance pistons have adequate

clearance but must be checked during assembly. Factory pistons may be

machined for added clearance. Valve to valve interference should be checked

with cams over 310° duration.

None of the listed cams will work in the

1977 750 F2 model Honda as valve to valve interference will occur due to the

larger diameter valve fitted. For the 1977 750 F2 engine, only one cam will

work. Grind number RB278SPC, Part #1005.

POWROLL

High Performance Billet Cams

These totally new cams, precision-machined

from billet steel, eliminate the need for an "exchange" with your present

stock cam. High-lift lobes are of the required contour without hardwelding

or regrinding. Choose from two different profiles engineered specifically

for Honda 750s.

|

FOR STOCK OR BIG BORE

displacements, this grind aids performance throughout the power

range. Although compatible with stock springs, we recommend the

use of our special valve springs. |

|

12661 |

Valve Opens |

Valve Closes |

Valve Lifts |

Running Clearance |

|

Intake |

19° BTDC |

46° ABDC |

.333 in. |

.004 in. |

|

Exhaust |

48° BBDC |

19° ATDC |

.325 in. |

.004 in. |

|

Note: All timing specs are

standardized at .040 in. valve lift and zero clearance.

Powroll Order No. 12661

|

FOR HIGH-DISPLACEMENT ENGINES

only, this cam is inappropriate for the stock 750. Provides

maximum engine-breathing capability for displacement over 900cc.

Compatible with stock springs, but operated more effectively

with Powroll's special valve springs. |

|

12662 |

Valve Opens |

Valve Closes |

Valve Lifts |

Running Clearance |

|

Intake |

23° BTDC |

53° ABDC |

.373 in. |

.004 in. |

|

Exhaust |

50° BBDC |

19° ATDC |

.350 in. |

.004 in. |

|

Powroll Order No. 12662

ANDREWS

PRODUCTS

|

Grind Number |

Timing |

Valve Lift* |

Duration** |

General

Characteristics |

|

A

STREET / STRIP |

20/40

40/20 |

.350"

.345" |

240°

240° |

Mild street cam for bolting into

stock 750 motors. No modifications or head work required. Stock

springs OK. More power thru RPM range; slightly higher idle speed;

smoothness unaffected. |

|

D

DAYTONA + |

19/45

45/19 |

.365"

.365" |

244°

244° |

Daytona; For modified and hotter

engines 750/850cc; much more power especially middle and higher RPM

ranges. Requires springs, spacing, and head work. Very streetable

but slight lope @ idle. |

|

K

SUPER STREET |

35/63

63/35 |

.375"

.365" |

278°

278° |

Super Street grind. Best for big

inch 750s (over 860 ccs) Strong pull from 5000/9500 RPM. Springs,

spacing, and head work required. |

|

4

DRAGS |

32/68

70/30 |

.400"

.400" |

280°

280° |

Hottest Competition Cam made for

750 engines! On a big inch dragster #4 cam yields more HP and lower

ETS than anything else available! Springs and head work required for

installation. |

*Maximum valve lift @ 0 Lash.

**Durations measured @ .050 valve lift; cam

@ 0 Lash.

R.C

ENGINEERING PERFORMANCE PRODUCTS

RACING CAMS: HONDA, 1969-78 CB750

RC240 Torque Cam - The only

R.C. Honda cam that can be bolted into a stock motor without piston valve

pocket machining. No head disassembly necessary. For smaller bore, low

compression motors. Good for road racing. (Sold as a regrind only - send us

your cam)

RC240 Timing:

|

Total Duration |

Lobe Centers |

Lift |

Lash |

|

296° |

118° |

.327" in.; .330" ex. |

.004" in.; .004" ex. |

RC295 Racer Cam - Smooth,

good idle and torque with lots of the top end. Quiet operation. Exceptional

for smaller motor. Ideal for 900cc motors.

RC295 Timing:

|

Total Duration |

Lobe Centers |

Lift |

Lash |

|

306° in./296° ex. |

105° |

.390" in.; .360" ex. |

.004" in.; .006" ex. |

RC315 Hot Racer Cam - Strong

torque curve from the ground up. Comes on low and never quits. This one

makes lots of horsepower. Very good for heavy street and altered race bikes.

Our favorite in the Street Class. Has flowed us to many national records.

Very tractable. Fair idle - quiet. Ideal for 900cc and larger motors.

RC315 Timing:

|

Total Duration |

Lobe Centers |

Lift |

Lash |

|

310° |

104° |

.365" in.; .365" ex. |

.012" in.; .012" ex. |

RC327 Full Competition Cam -

Similar to #315, but with more lift and overlap. Designed with more duration

for maximum revs and BHP on all big motors. The best choice for use in

1000cc motors.

RC327 Timing:

|

Total Duration |

Lobe Centers |

Lift |

Lash |

|

325° |

104° |

.368" in.; .368" ex. |

.012" in.; .012" ex. |

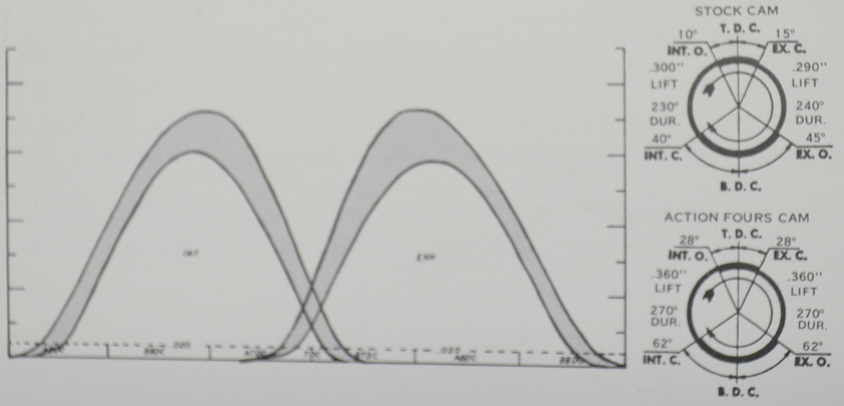

ACTION

FOURS

We use new, cast billets exclusively.

Regrinds are cheaper, but there is not enough material to obtain an

efficient profile and adequate base circle dimensions.

Stock pistons cannot be used with any cams

we sell. You would not get your money's worth. A proper profile that would

give safe valve-to-piston clearance would not increase performance

significantly. A cam that would give clearance and increased performance

could not have a safe profile. Notching stock pistons is not of much value

either, since a hot cammed, low compression motor is a very poor performer.

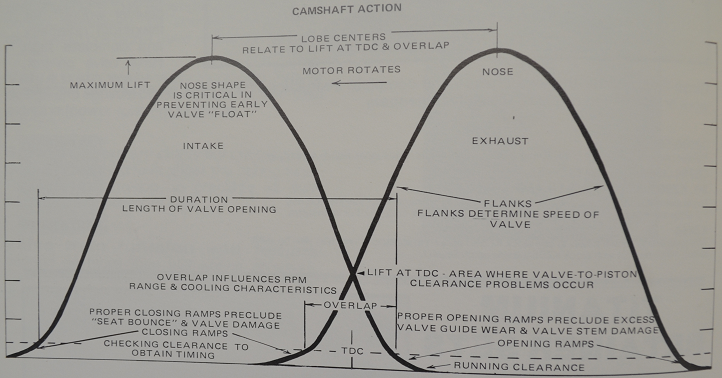

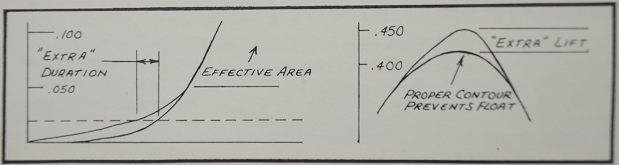

Lift and duration figures are real. The

drawing below shows how "extra" lift and duration may be added to no

advantage. Buying the "biggest number" without regard to proven results is a

fool's game.

THE "NUMBERS GAME"

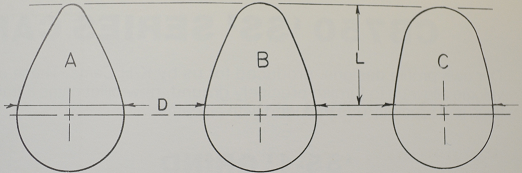

Are the cams above the same? They are

by the "numbers"!

Cams A, B, and C above all have the

same lift (shown at "L") and duration (shown at "D"). Yet, there are

obviously very different. If cam B is correct in design, then cam A

would give good "low end" but less H.P and float the valves more easily.

Cam C would have plenty of "top end", but would exhibit a narrow power

band and open the valves too rapidly for good reliability.

No degreeing-in is required if stock

components (tensioner, cam chain, etc.) in good condition are used. All

our cams are indexed from the sprocket mounting rather than the drive

slot. This insures far greater accuracy for "drop in"

installation.

|

|

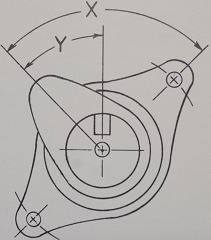

Most cams are located for

grinding from the keyway as shown at "Y". The same

arrangement is used on Kawasaki cam but is removed after

grinding. All our cams are located from the mounting bolt

holes, as shown at "X". Since the bolt holes determine the

cam location, "spot on" results. The keyways becomes your

"which tooth" indicator only. Of course, this applies to

standard components in good condition only. Milling the head

or cylinder, or using non-standard or badly worn parts will

affect actual timing. |

Is

±11° good enough for

you?

Big valves cannot be used in most

cases. As overlap increases, valves come closer together. In our

experience, an unrestricted profile will do more for performance

than oversize valves. More latitude for cam timing variations are

possible with stock valve sizes, too.

Carefully designed and tested

profiles prevent excess stress and premature float. Extreme,

power-robbing valve spring pressure is not required.

|

To test for adequate

valve to piston clearance with any cam, rotate the

nearest cylinder slowly to the overlap (exhaust closing,

intake opening) position. Rotate the motor slowly,

stopping every few degrees, from 35° BTDC to TDC (top

dead center). Each time you stop, depress the exhaust

valve follower (a padded screwdriver works well) until

the valve contacts the piston. The point at which the

valve moves the least is your minimum clearance and it

may now be measured. In no case should it be less than

1mm (.040"). Reverse the procedure (TDC to 35° ATDC) to

check intake valve clearance. Advancing the cam (forward

in relation to motor rotation) will increase exhaust and

reduce intake clearance. Retarding the cam has the

opposite effect. |

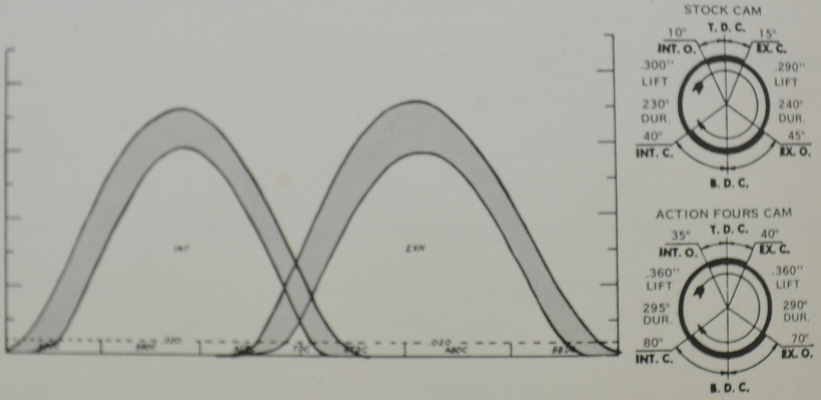

CB750 'SS'

SERIES CAMSHAFTS

'SS-1' GRIND

|

|

High 11, low 12 second 1/4 mile

times (used with 811cc Bore Kits) yet as smooth and tractable as a

stock machine! This is definitely the cam for those riders who are

worried about their "hot" cams.

May be used with stock valve

springs for economic applications. Of course, we recommend a

complete racing valve spring set for an even wider margin of

over-rev protection.

|

Camshaft

Only |

PART # 19-101 |

|

Cam &

Racing Valve Spring Set (Except F2) |

PART # 20-101 |

|

Cam &

Racing Valve Spring Set (F2 Models) |

PART # 20-201 |

|

Note: The SS-1 may be safely used in F2 (large valve head)

models, without valve modification.

'SS-2A' GRIND

|

|

For maximum acceleration. Preferred

by those who are serious about drag racing, yet need a certain

degree of tractability. Best power from 6,500 up. Racing valve

spring set is recommended.

|

Camshaft

Only |

PART # 19-102 |

|

Cam &

Racing Valve Spring Set (Except F2) |

PART # 20-102 |

|

Cam &

Racing Valve Spring Set (F2 Models) |

PART # 20-202 |

|

For the best performance and reliability use them cams

with Action Fours high compression big bore kits.

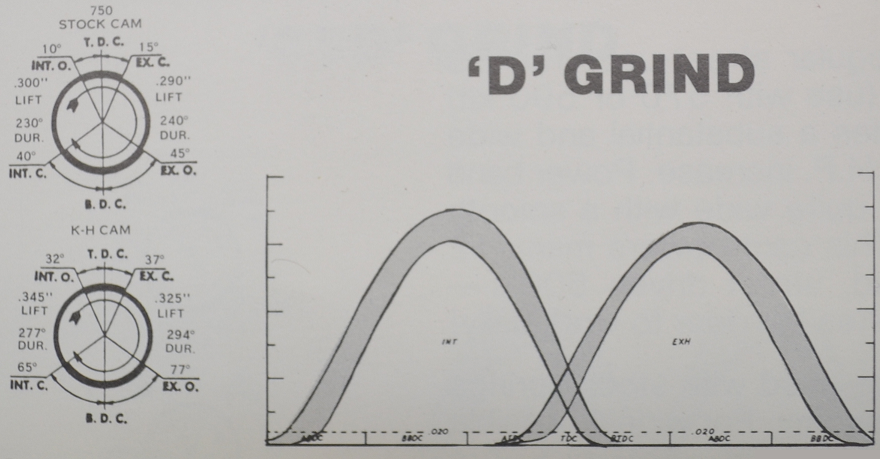

Kenny Harmon's 35 years of cam

design and grinding experience are manifest in these excellent

profiles. 750 Honda cams from K-H have become an industry

standard for quality and performance. All cams are precisely

indexed for "spot-on" timing.

'D' GRIND

|

|

A famous grind. Excellent for

riders who desire a major H.P increase, but insist on a wide range

of us. Well balanced with reasonable idle and "low end" and a major

increase in acceleration. Long exhaust duration allows for sustained

high speed cruising without excess combustion chamber temperature.

May be used with stock springs if

desired. For greatest reliability our racing valve spring set is

recommended.

|

Camshaft

Only |

PART # 19-103 |

|

Cam &

Racing Valve Spring Set (Except F2) |

PART # 20-103 |

|

Cam &

Racing Valve Spring Set (F2 Models) |

PART # 20-203 |

|

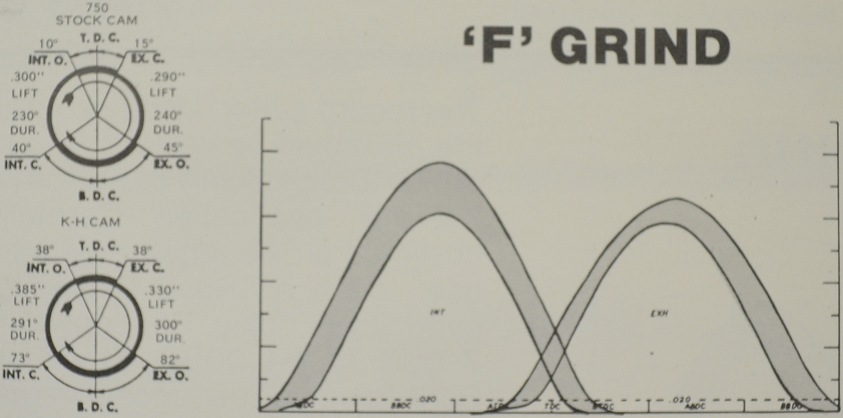

'F' GRIND

|

|

For the greatest H.P possible,

consistent with sustained use. Extra long exhaust duration and

substantial intake area provide record setting H.P, as well as

efficient temperature control.

The best choice for road racing and

other "top end" applications. Best power 7-11,000 RPM.

May be used on the street or for

drag racing with very low gearing. Should be used only

with racing valve spring set.

|

Camshaft

Only |

PART # 19-104 |

|

Cam &

Racing Valve Spring Set (Except F2) |

PART # 20-104 |

|

Cam &

Racing Valve Spring Set (F2 Models) |

PART # 20-204 |

|

SUPER 'F' GRIND

|

|

The ultimate DRAG RACING ONLY

cam. ABSOLUTELY NOT FOR STREET USE.

Extreme valve lift is combined with

over 300° intake and "short" exhaust timing to get off the line hard

and accelerate to high RPM.

No compromises in profile design

whatever. This cam is not suitable for for any sustained use. Should

only be used with complete racing valve spring set.

|

Camshaft

Only |

PART # 19-105 |

|

Cam &

Racing Valve Spring Set (Except F2) |

PART # 20-105 |

|

Cam &

Racing Valve Spring Set (F2 Models) |

PART # 20-205 |

|

For the best performance and reliability use them cams

with Action Fours high compression big bore kits.

A 3.99% customer service

charge is applied to all phone orders.

If ordering via phone,

please also provide the part # of any products you are interested in for faster

and more accurate service.

If you encounter a (rare)

broken button as you're trying to add parts to your cart (going to PayPal

summary instead of your cart or not opening PayPal at all) or anything else of

concern, please call us to report it. We'll try to have it fixed for your

convenience within the next 5-10 minutes. Afterwards, refresh the page and try

again.

NOTE: As of July 1st,

2018, an extended goods and services tax (GST) has been applied to all

Australian consumers buying overseas, charging an extra 10% in taxes to us with

each purchase. To ensure that you can continue to purchase from us in Australia

and we can provide our parts at our usual lower cost, please

contact us at the email below if interested in any particular

parts so that we can make a special shipping arrangement for you.

It is the sole and

exclusive responsibility of the purchaser to determine the suitability of any

part, product or work for his or her use.

The purchaser shall assume all legal, personal injury risk and liability and all

other obligations, duties and risks therewith.

There is no warranty on High Performance products.

Click

to go back to our home page

Cycle

X Global Headquarters

6246 US

Hwy 51 South

Hazelhurst,

WI 54531

Phone:

715-356-7346

Email:

hotrodcyclex@gmail.com